ELECTRICAL ENGINEERS ROLE IN FACILITY MANAGEMENT

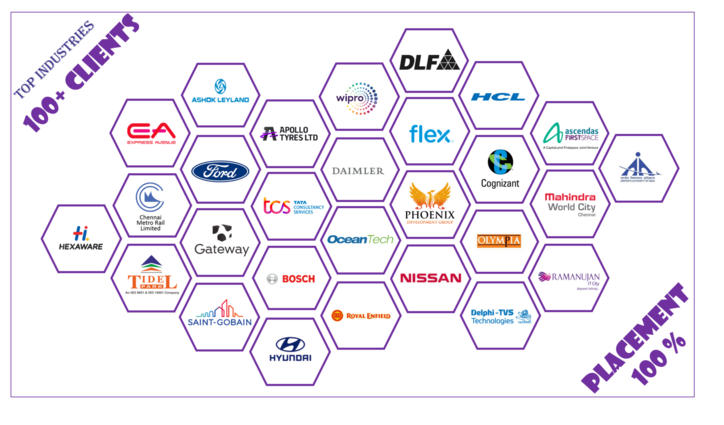

"IIFM is generally observed that Degree Completed youth have not produced desired result because teaching imparted in college alone is not enough for acquisition of skills but needs to be supplemented by training in the actual world of work. So IIFM fill these “Technical Skill-Gap” as well as it leads to Success in Placements too"

Substation maintenance is a process of periodic, planned inspection of and, if necessary, repair, and replacement of all switchgear, buildings, and ancillary equipment in substation installations. Substation maintenance is a process of periodic, planned inspection of and, if necessary, repair, and replacement of all switchgear, buildings, and ancillary equipment in substation installations. In simple terms, substation maintenance is a regimen of regular preventative checks and actions carried out to ensure substations are kept in good working order. This process typically consists of a series of stringent visual and physical inspections and actions carried out according to a set schedule. Equipment replacement may be standard procedure or only upon detection of wear, damage, or substandard operation. All inspection and actions during substation maintenance should be accurately documented and stored for further reference.

Substations are the most critical part of any electrical supply grid. A failure of a single piece of substation equipment can cause a total grid collapse which may take days or even longer to rectify. For this reason, substation care is one of the most important parts of any electrical department’s preventative maintenance schedule. These schedules generally consist of a tiered plan of minor and major maintenance events. Minor maintenance will seldom require any sort of power shut down although major events typically requiring short intervals of supply interruption. Routine or minor substation maintenance is usually carried out on a weekly or bi-weekly basis. It typically consists of visual checks and superficial cleaning only. Checks would include visual confirmation of the general condition of switchgear, earthing mechanisms, transformers, insulating liquid levels, and lightning arrestors. A general system performance check can also be carried out using any installed software or by reviewing incoming and outgoing meter readings. These checks are generally implemented in accordance with a set checklist and all findings are noted and filed. Major substation maintenance involves more planning and is generally handled on a quarterly basis. In the case of industrial installations, these procedures are often carried out during plant maintenance shutdowns. Residential substations are a little more difficult to plan for and generally require switching the supply over to auxiliary equipment during the process. During these maintenance events, a more detailed checklist is followed which requires checking and testing individual substation components. This will typically require isolating individual circuit breakers and checking racking mechanisms, overcurrent and earth leakage protection, and contact integrity.

Supplementary Skilled Courses:

- Electric Power is the main source of our daily life activity and use of Electric Power is increasing every day in the world. Electricity is being generated through various sources i.e. thermal, hydro, nuclear, solar etc. but its transmission, distribution and utilization is almost everywhere in the world.

- Consequently, trained man power is very much required at every level i.e. generation, transmission, distribution and utilization.

- Whole electrical network is increasing every moment and making network more Industry. To operate the complex network of Generation-Transmission-Distribution-Utilization, trained skilled man power is very much needed.

- Institutional study and theory is the base of understanding of this subject matter but on job training is necessary to make a person employable and capable on the work front.

- In view of the above, to develop such type of skilled manpower; to meet the demand of the time and industry, person should be trained for the actual need i.e. he should be able to know the all major HT, LT equipment like motor, generator, substations, transmission through overhead lines and underground cable

- Fault finding of these machines, repairing and maintenance. DC machines are also a part of our industries and application, operation and repairing of those DC machine is also a part our technical activity. Use of Solar Energy is the future and skilled man power in this area will be in demand.

- A large number of skilled workers coming out of technical colleges do not possess the required skills and are not readily employable. The industries have to spend time and money on their training. It has been observed that most of the existing Industrial Training Institutes run by the government and private sector do not have on the job training facilities.

- Therefore, IIFM is to develop their Knowledge into Technical Skill to Entry the Core Industry and Success with their Career up to Facility Manager Level.

Diploma in Power Plant Operation & Maintenance Engineering

.gif)